National Major Special Project for Instruments

Development and Application of High end Electromagnetic Testing Instruments Based on Variable Frequency Domain

Founder/CEO

Ph.D. in Materials Processing Engineering, Tsinghua University

Host and undertake

national, provincial and ministerial level

scientific research projects

The Ministry of Industry and Information Technology's Large Aircraft Project

Research on Key Technologies of Laser Ultrasonic Testing and Calibration

Joint Lab with NAIMTC

Exploring innovative and collaborative work models to enhance the capabilities of industrial measurement and enterprise measurement, and achieving high-quality development of both parties in terms of operational mechanisms, scientific research cooperation, technical services, and achievement specialization.

Innovation Fund of the Ministry of Science and Technology

Digital ultrasonic diffraction sound time detector

Public welfare industry research projects

Research on Testing Standards for Ultrasonic Diffraction Sound Time Method

Beijing University of Technology

Chinese Academy of Engineering

Conference on Nondestructive Testing of Batteries and Semiconductors

Ultrasonic Committee of the Nondestructive Testing Society

China Committee for Nondestructive Testing Standards

Beijing Nondestructive Testing Training Center

China Committee for Nondestructive Testing Equipment Standardization

China Committee for Testing and Standardization of Materials

IInternational Science and Technology Cooperation Program

ASNT Beijing Chapter

Beijing “Science and Technology Rising Star”

Mainly engaged in safety testing and quality evaluation of new energy lithium batteries, as well as research on non-destructive testing (NDT&NDE) of materials, non-destructive testing (NDT&NDE) in advanced manufacturing technology, online automatic testing, and intelligent quality diagnosis and control.

Beijing Municipal Commission of Science and Technology Industry University Research Project

Digital ultrasonic testing instrument

Quality inspection public welfare industry research special project

Research on Key Technologies and Standards for Non destructive Testing of Cast Iron Pressure Equipment

Development of International Standard for Non destructive Testing Infrared Testing Equipment

.......

High end electromagnetic inspection based on variable frequency domain, a national key research and development plan project during the 13th Five Year Plan period

Research on in-situ inspection and evaluation technology for important components of electromechanical lifting special equipment and equipment development

NDT Technology Innovation Center Lab co-established with CSEI

(1) Research and development of new methods, technologies, and processes for non-destructive testing;

(2) Research and development of advanced non-destructive testing equipment;

(3) Application of advanced non-destructive testing technology;

(4) Ability testing and evaluation of testing personnel, equipment, and processes;

(5) Special equipment industry testing technology services and management.

Industrialization Project in Haidian District, Beijing

Industrialization of digital ultrasonic flaw detectors

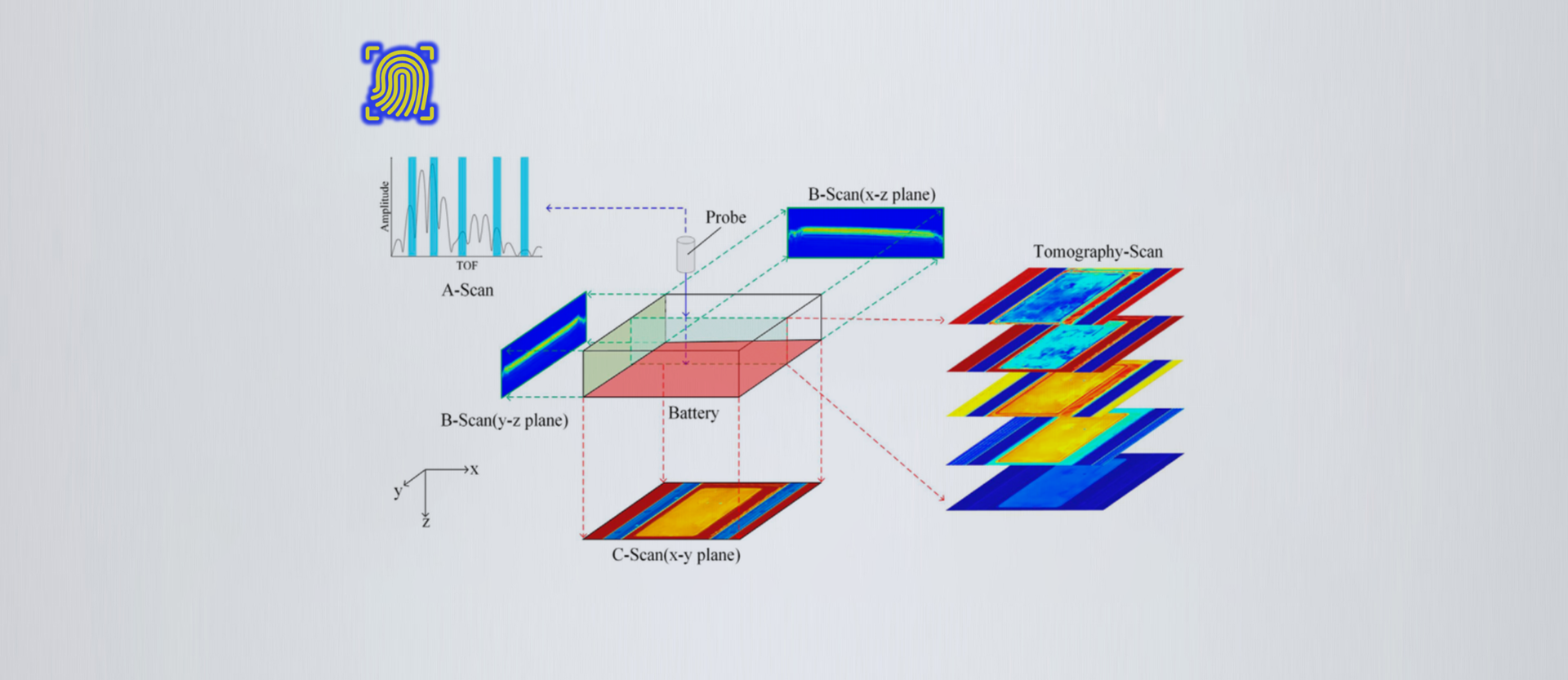

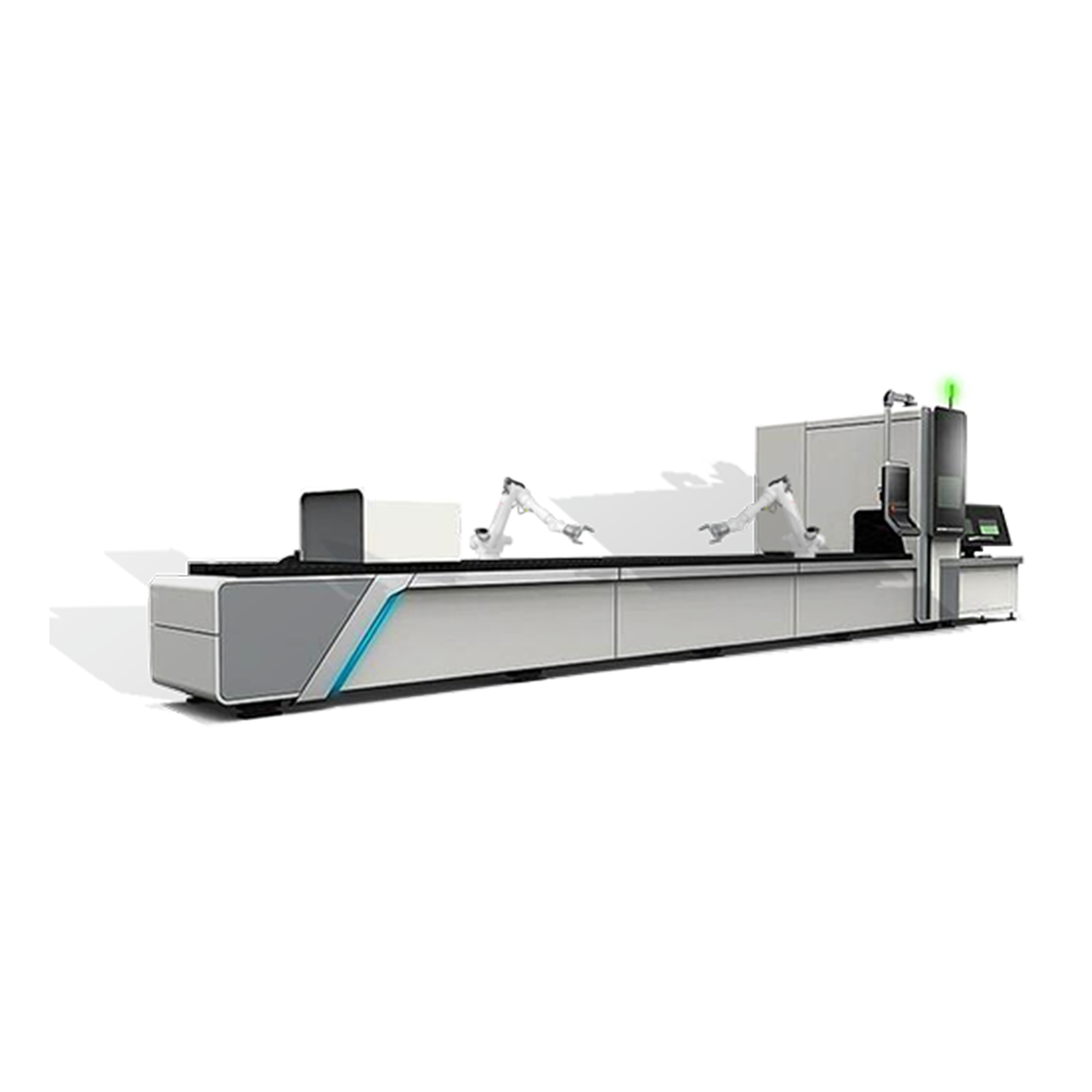

Dual modes of air coupling and liquid immersion, supporting 3-channel detection with detection accuracy less than 1mm, suitable for detecting soft pack, cylindrical, and button batteries.

The dual detection mode can detect defects up to 1mm, suitable for soft pack, hard shell, cylindrical, and blade batteries.

Doctoral Supervisor

Consulting Expert

Chairman/President

Vice Director

Deputy Secretary-General

Director

Committee Member

Committee Member

Evaluation Expert

Chairman of the Board

Beijing Outstanding Talent

"Joint NDT&E Lab for New Energy Batteries" with GZCTC